The Spark III C50 mast is an excellent choice for general freeride blasting and progression.

Loftsails utilizes high-quality pre-preg construction methods in production, making Spark III much more than just an entry-level mast. With its superior reaction and performance, it can rival many higher carbon-content mast models.

The solid construction of the Spark III mast provides peace of mind and ensures durability for long-lasting use.

Product highlights

Quality control

Each mast produced is being checked and controlled

Constant Curve

Mast features most common bend curve. Works perfect with Loftsails and with most other manufacturers sails

Perfect balance

Optimal price to quality ratio

Features

Loftsails mast manufacturing standards

Loftsails masts are manufactured using only the highest-grade materials and pre-preg (fiber cloth that’s pre-impregnated with resin) construction methods that are highly consistent for quality control and superior to traditional ‘wet’ layup processes that do no guarantee even resin transfer, strength and performance. Loftsails use superior T800 & T700 carbon fiber in their masts. T800 is the optimum fiber when under strain and elongation and compression and also delivers superior response action that enhances sails so well. T700 has even more superior resin absorption and consistency and in fact Loftsails leading Team Edition masts use both fabrics for the ultimate blend of quality and performance.

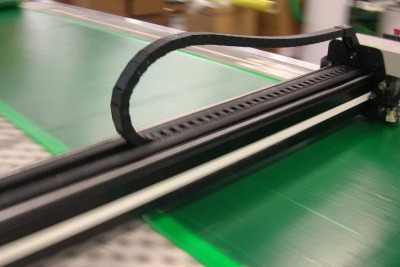

Accurate materials specifaction

The CAD plotter accurately cuts all composite raw materials used in the process. This is vital for consistency of weight control and performance.

Taking shape mandrels

The right mandrel for each model is then chosen so that the required taper, thickness, bend curve and many other characteristics specified for each model can be produced.

Layup and dressing

For confidentiality reasons we cannot show Loftsails’ precise, classified techniques used in the next stages. These steps involve rolling the plotted composite materials onto the mandrel with a closely guarded process on how the unique inner and compression layups are formed and secretive method for how the ferrules are integrated. The stickers are applied at this stage though!

Taping

External finishing such as protective basalt layers and durable finishing tape are applied to protect from camber wear, heat and impact.

Curing

The mast is cooked in an autoclave. It’s vital to closely monitor and precisely control the curation process at various stages for the most consistent results.

QC

Quality Control checks are made such as bend curve measurement, strength under load and impact. Final finishing inspections are then completed before packaging. Next stop – the beach!

For instant answer - open the chat and ask your question. We're active 9.00-17.00 CET.

Is it afterhours? No problem - leave us a message and we’ll respond early the next day.

+48 513 020 570

For those who prefer phone calls - that's our number. You can give us a ring between 9.00-17.00 CET.

Facebook

Facebook Instagram

Instagram YouTube

YouTube