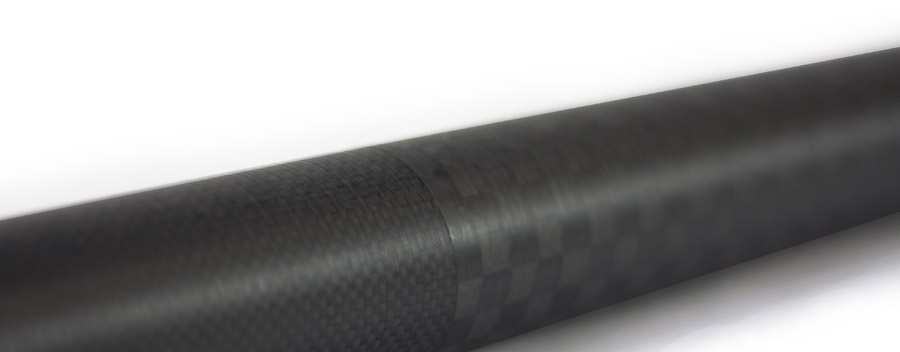

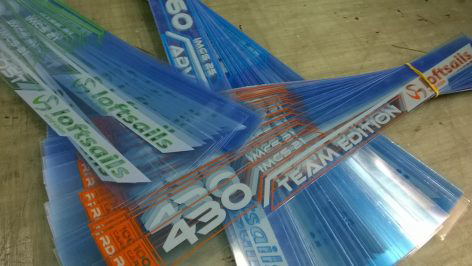

TEAM EDITION 100% CARBON SDM

-

SIZES: 370 / 400 / 430 / 460 / 490 / 520 / 530 / 550

Loftsails Team Edition masts are focused on achieving the best possible response for the least possible weight, without compromising durability. In high-performance sails, reaction and reflex are critical and having that pre-set, intended behavior pre-set and consistently replicated in all diameters and sizes of the mast program is the number one requirement in complementing their test-winning sails. Using the best possible T700 and T800 carbon fibers and pre-preg (pre-impregnated with resin for the best possible quality vs. traditional wet layup processes) methods, Loftsails autoclave-cured process delivers the highest standard of tensile strength, impact/friction protection and responsive flex available – all from a bespoke, dedicated program – unlike many brands that rely on off-the-shelf OEM products alone.

FEATURES & BENEFITS

- Constant Curve Bent Curve

- Highest specification SDM mast

- Each mast produced is being checked and controlled

- Mastbag included

LOFTSAILS MAST MANUFACTURING STANDARDS

Loftsails masts are manufactured using only the highest-grade materials and pre-preg (fiber cloth that’s pre-impregnated with resin) construction methods that are highly consistent for quality control and superior to traditional ‘wet’ layup processes that do no guarantee even resin transfer, strength and performance. Loftsails use superior T800 & T700 carbon fiber in their masts. T800 is the optimum fiber when under strain and elongation and compression and also delivers superior response action that enhances sails so well. T700 has even more superior resin absorption and consistency and in fact Loftsails leading Team Edition masts use both fabrics for the ultimate blend of quality and performance.

TAKING SHAPE – MANDRELS

The right mandrel for each model is then chosen so that the required taper, thickness, bend curve and many other characteristics specified for each model can be produced.

LAYUP AND DRESSING

TAPING

CURING

QC

For instant answer - open the chat and ask your question. We're active 9.00-17.00 CET.

Is it afterhours? No problem - leave us a message and we’ll respond early the next day.

+48 513 020 570

For those who prefer phone calls - that's our number. You can give us a ring between 9.00-17.00 CET.

Facebook

Facebook Instagram

Instagram YouTube

YouTube