JP-Australia's SUP boards technologies and constructions.

JP-Australia has years of experience and many successes in windsurfing competitions. The knowledge gained in this field has been used by the company to create its collection of SUP boards. JP inflatable boards have been in their collection since 2014, and since then, the technology used to produce them has been continuously developed. In the article below, we present the technologies and constructions of JP-Australia inflatable SUP boards.

TECHNOLOGY

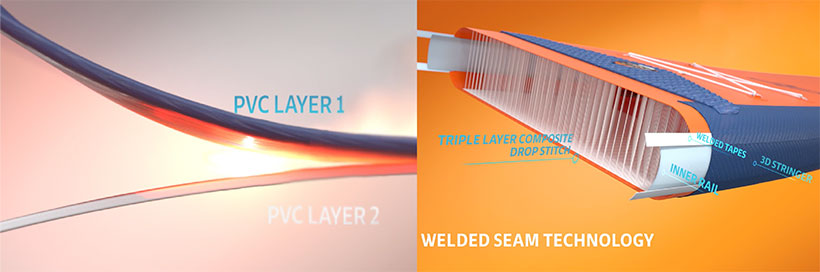

JP strongly emphasizes the quality of its products, which is why it is currently one of two companies on the market that use the Welded Seam Technology (technology of joining seams by welding at high temperatures). The percentage of warranty claims for JP boards produced using this technology is zero! As the company admits, they've never had a product with no warranty claims, as is the case with iSUP boards (inflatable SUP).

Welding process

The first layer of the rails and the bonding tape is welded with hot air to the drop stitch material, creating a long-lasting mechanical connection. This creates a very strong mechanical connection, which turns the edge, tape, and drop stitch material into one inseparable part.

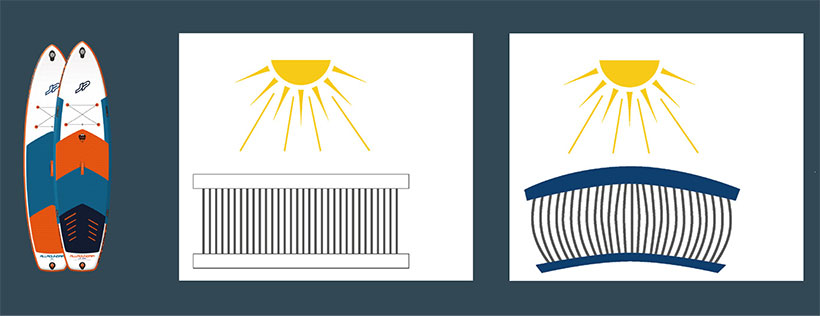

Over the last few years, JP has paid attention to another important factor that affects the quality and durability of inflatable boards, namely temperature. Through multiple tests of their own and competitors' products, exposing them to the sun, and keeping them on the roof for several days, the brand has come to a very significant conclusion. It turned out that coloured boards are much more susceptible to damage caused by the sun, which is why white is the dominant color in the JP inflatable SUP collection.

White JP-Australia boards

White PVC

- White PVC material doesn't absorb heat

- The material on the deck and bottom (sunny side and shady side) remain the same

- No deforming effect

Coloured PVC

- The heated side of the PVC material expands and stretches

- Shaded side doesn't change shape

- This causes deformation due to the difference in size between the deck and the bottom

Technologies developed by JP are behind the uncompromising quality offered by the manufacturer. All JP-Australia SUP boards are produced in four different construction versions. Each of them was created with different users in mind and also affects the price of the SUP. To better understand the differences between them, we've prepared a special graphic explaining each one.

JP INFLATABLE CONSTRUCTIONS

SUPER LIGHT

The first layer of PVC guarantees 100% tightness of the board, while the upper layer of PVC creates a laminated structure, making the board incredibly light. Super Light is the most economical version of JP inflatable boards, ideal for people starting their SUP adventure. Features: bungee cord, two-color EVA pad on the deck, comfortable handle and double layer drop stitch.

All JP inflatable constructions feature:

- EVA foam pad

- Diamond groove for ultimate traction and comfort.

- Valve - safe, fast, and easy to use

- US BOX fin box standard

- Doesn't require the use of special tools.

LIGHT EDITION

The Light Edition is a two-layer, pre-laminated construction that guarantees an incredibly low weight. The two layers of machine-laminated PVC that do not allow air to pass through create a durable coating of ideal thickness. Then is directly laminated onto the 500D Polyester Drop Stitch fabric. JP offers LE boards in both 5'' and 6'' thickness.

PRE-LAMINATION

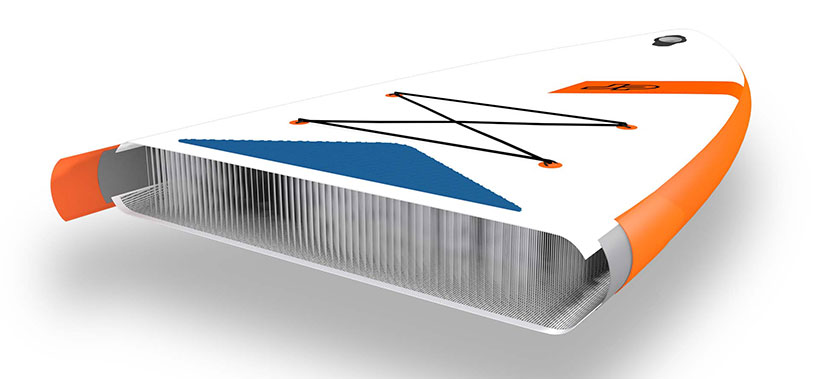

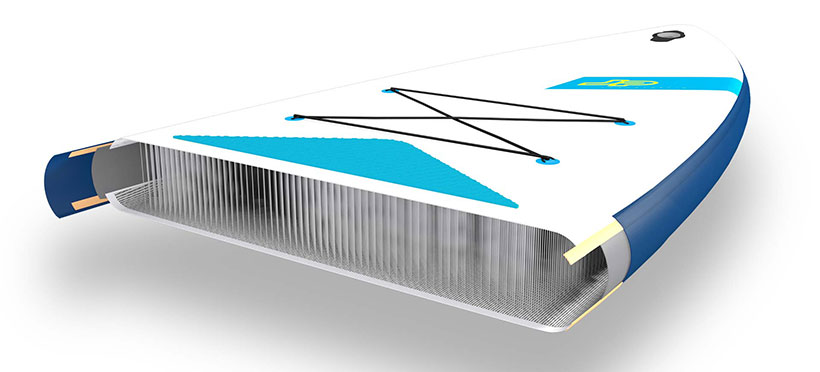

Triple Layer Composite and Double Layer constructions use a specially developed pre-lamination process. This technologically advanced process involves machine-laminating multiple layers into a shell that has the perfect thickness and excellent resistance to wear and tear. Compared to typical two-layer boards, the manual application of glue has been eliminated, reducing the chance of error, excess weight of glue, and risk to JP employees' health. Fiber-reinforced layers create super-strong and durable boards with minimal stretch.

LIGHT EDITION 3D STRINGER

The laminated Light Edition construction is exceptionally lightweight. Two layers of machine-laminated PVC that do not allow air to pass through create a durable coating of optimal thickness. This is then laminated directly onto the 500D Polyester Drop Stitch material. JP offers LE 3DS boards in both 5'' (12.5cm) thickness (for lighter riders) and standard 6'' (15cm) thickness.

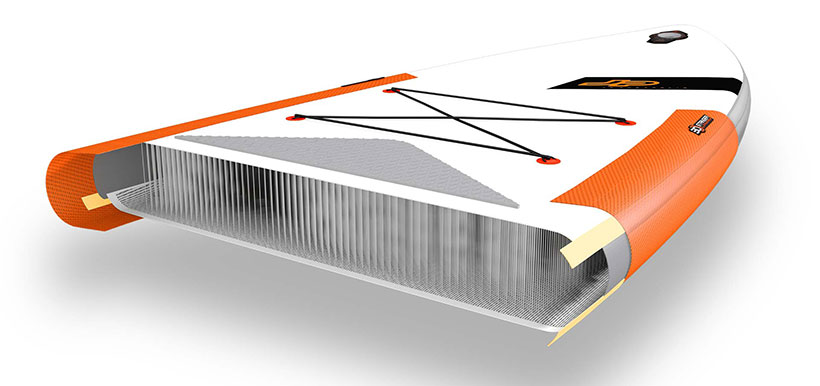

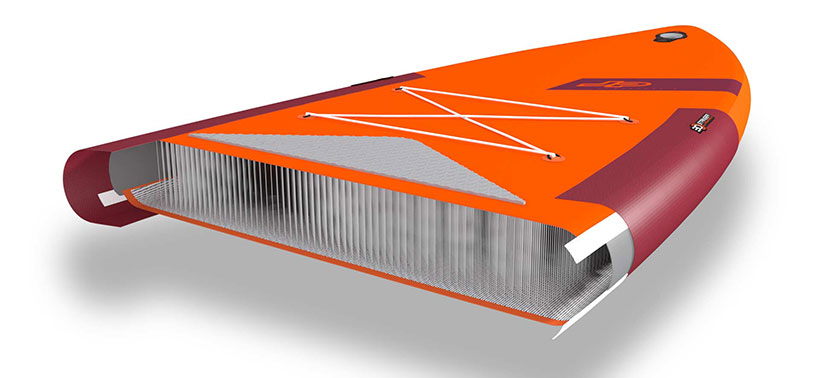

3D STRINGER

3D STRINGER is the most innovative solution for increasing the stiffness of an inflatable board. It combines the deck, rails, and bottom into a single U-shaped structure. This solution has increased board stiffness by 30%! In addition, the 3D Stringer increases the surface area of overlapping layers in the most heavily loaded areas of the deck, improving the durability and safety of the boards.

SUPERIOR EDITION 3D STRINGER

Three pre-laminated composite layers consist of two PVC layers responsible for sealing, connected to a 1000D Polyester material to create a super-strong coating. This is then machine-laminated directly onto the 500D Polyester Drop Stitch material. The pre-lamination method and composite structure provide an unprecedented ratio of weight to stiffness and durability in inflatable SUP boards. SE 3DS boards are offered in a 6'' (15cm) thickness, except for the SurfAir 9’7”x32” (4”/10cm)).

BOARD SHAPE

In addition to the technology behind JP's SUP construction, the shape of the boards is also a significant differentiator. We need to consider it in two dimensions. One is the shape of the board when viewed from above. Most manufacturers' boards have an oval shape, while JP boards have a more parallel outline. The benefits of such a shape and precise differences can be seen in the graphic below.

Parallel JP'S rail shape

FEATURES:

- A narrower nose cuts through the water better, resulting in higher speed and greater paddling efficiency.

- Parallel rails provide excellent directional stability, so you won't have to constantly switch your paddle from hand to hand.

- A wider tail significantly improves the board's stability.

Drugą cechą, która wyróżnia kształt desek JP jest linia rockera, którą można zobaczyć, gdy spojrzymy na deskę od boku. Rocker polega na odpowiednim wyprofilowaniu i uniesieniu dziobu oraz rufy deski od płaszczyzny poziomej. Zbyt duży rocker będzie spowalniał deskę, ponieważ zbyt duża ilość wody będzie dostawała się pod deskę, zwiększając opór (dotyczy to zarówno dziobu jak i rufy). Jednak trzeba pamiętać, że są sytuacje, w których większy rocker jest potrzebny, a ma to miejsce w przypadku pływania na falach. Zjeżdżając z fali na desce ze zbyt małym rockerem, dziób może nam się wbić wodę i zatrzymać deskę w miejscu.

The second feature that distinguishes the JP's boards shape is the rocker line, which can be seen when looking at the board from the side. The rocker refers to the proper shaping and lifting of the board's nose and tail from the horizontal plane. Too much rocker will slow down the board, as too much water will get under the board, increasing drag (this applies to both the nose and tail). However, it should be remembered that there are situations where a larger rocker is needed, e.g. surfing waves. When riding a wave on a board with too little rocker, the nose can dig into the water and stop the board in its tracks."

The subtle line of JP's rocker.

FEATURES:

- The subtle line increases waterline performance by reducing drag

- A sharply finished tail increases the performance of the board by quickly releasing water from under it.

- All of this results in a better glide on the water after each paddle stroke.

SUMMARY

As we can see, the technology and construction of inflatable boards have a significant impact not only on the durability of the SUP, but also on its performance. JP-Australia, thanks to its experience in the water sports industry, creates products that are technologically distinctive in the market. Each of the mentioned board constructions was created with different target groups and price categories in mind. I hope that this article'll help you to make a choice about the appropriate board construction for you.

JP-Australia’s 2025 Innovations – Collection Overview!

JP-Australia, a leader in the windsurfing industry, has just revealed its 2025 collection, bringing new technology, updated shapes, and innovative boards to elevate the water sports experience. From the groundbreaking S-TEC construction to enhanced designs of classic models and specially crafted boards for kids, the brand continues to focus on quality and excellence in every detail. Read on for a closer look!

Loftsails 24/25 collection

We are thrilled to present the latest 24/25 Loftsails collection, now available for pre-order! This exciting line results from innovative technologies and years of experience that Loftsails has gathered in the world of windsurfing. Get to know the description of each model.

PLKB 2025 Collection – Kites and Gear for Kitesurfing, Snowkiting, and Landkiting!

Since we have launched preorders for 2025, and we are excited to present the entire collection from PLKB (Peter Lynn Kiteboarding). For years, this brand has been offering high-quality gear for kite, snow, and land kiting, allowing every kite sport enthusiast to find something suited to their needs, regardless of the terrain or season. PLKB’s extensive experience in creating kites that exceed expectations sets them apart, making every session enjoyable and thrilling. PLKB has taken on the challenge of outperforming major brands, overcoming all obstacles along the way.

Exocet boards collection review for 2024/2025. Available for pre-order!

Meet EXOCET's collection of windsurfing boards for the 2024/ 2025 season, which is now available in pre-order! In the range of this french brand you will find constructions for classic windsurfing on the fin, as well as for foil. In this article we will acquaint you with the individual models to help you choose the right equipment for yourself ;) Don't hesitate to sign up for a preorder and get the latest model at a favorable price!

Win a NeilPryde Waterwear wetsuit!

Together with NeilPryde Waterwear, we're announcing a contest where you can win any wetsuit from the NeilPryde's range. Check the details below:

King of the Bay report!

What a weekend it was!!! 🤩 Rewa welcomed us royally! For four days, we enjoyed beautiful sunshine and conditions that allowed us to not only hold the planned races but also to carry out all other activities. The turnout exceeded our wildest expectations. Over 240 competitors registered for the event, and in addition to the participants, crowds of water sports fans flocked to Rewa. Everyone came with one goal: to spread passion and love for windsurfing, kitesurfing, wing foiling, SUP, and pump foiling! I'm still not fully recovered from this magical water sports festival, but the boost of positive energy and motivation we received, both myself and our entire EASY-surfshop team... It's simply indescribable! So much happened during these four days, and the event itself could be divided into two parts: racing and festival-market, which I'd like to briefly present to you.

What kind of wetsuit to choose? - learn tips to help you choose the right wetsuit

Are you planning to embark on a windsurfing, kit or foil adventure? If so, the first thing you will need is definitely a neoprene wetsuit, it will be an integral part of your equipment. The variety of wetsuits on the market can be overwhelming, so we'll give you a brief overview of the key elements when choosing the right one, but let's start with what exactly are they?

Gladiator SUP board collection review for 2024

SUP is an increasingly popular water sport that combines elements of recreation, training and adventure. If you're passionate about water activities, you've certainly heard of the Gladiator brand. Take a virtual tour of their SUP board collection for 2024!

Facebook

Facebook Instagram

Instagram YouTube

YouTube