NEILPRYDE Fly wing 2023

- Sizes: 1.4 / 1.8 / 2.2 / 2.5 / 2.9 / 3.3 / 3.6 / 4.0 / 4.3 / 4.7 / 5.0 / 5.4 / 5.7 / 6.0

NeilPryde team does know they'll never outrun evolution. However, the NeilPryde ethos has always been committed to the best engineering humanly possible. To performance, innovation and top-quality, long-lasting products. After 2 years of development, they're confident that they've pushed the boundaries of what's possible again with the first NeilPryde wing.

The development of the FLY has been based on using the most proven materials, examining the technical development of wingfoiling down to the smallest detail and adjusting all the set screws. With Nils Rosenblad - former NeilPryde sail designer and Americas Cup foil engineer - and entire design team dedicated to this project, the first NeilPryde wing introduces several unique features and innovations. The whole is greater than the sum of its parts and many of these small technical innovations, not at all visible at first glance, that make the difference here. Born from the unconditional view of the Wing from the perspective of an engineer, sailmaker, and flow expert.

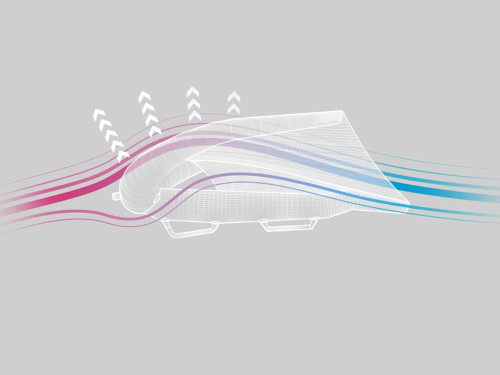

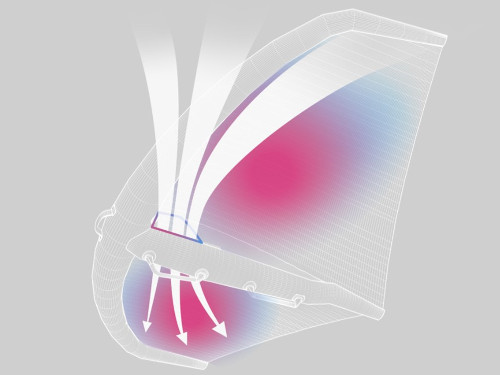

It was clear from the beginning that they didn't want to look at a Wing as a kite without lines, but had to adapt all design features to the specific requirements of a high performance Wing. The essential concept of the Fly is based on their new High Lift Coefficient. Every single size of the Wing has been optimized and adjusted to produce more lift, more thrust, and less drag than other wings of comparable size. This makes the Fly easier to handle, more comfortable and efficient to fly, and more convenient to transport. To achieve this, they have taken and adapted design elements from sailing, windsurfing, aircraft design and foil design.

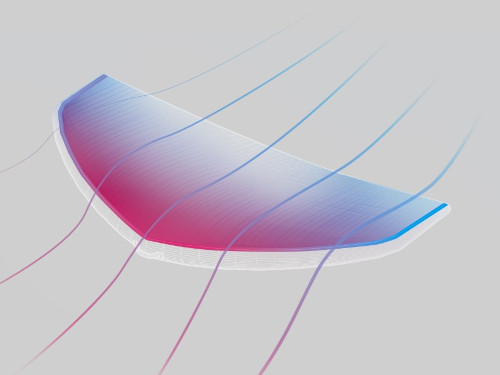

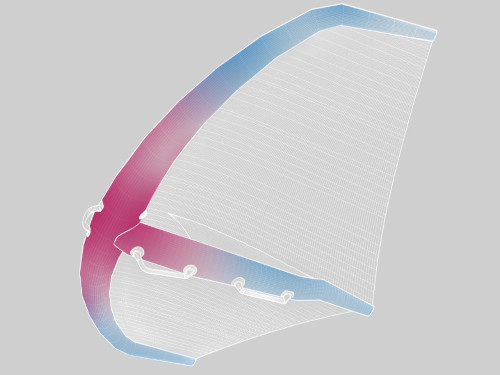

NeilPryde wing shapes are high aspect, which means that the span between the opposing wing tips is relatively large. At the same time the dihedral front profile of the leading edge prevents the wing tips from dipping into the water. FLY generates the exceptionally strong thrust through very high canopy tension in the front part of the wing, which guarantees a stable profile and an ideal airflow over the wing, even at very high angles of attack.

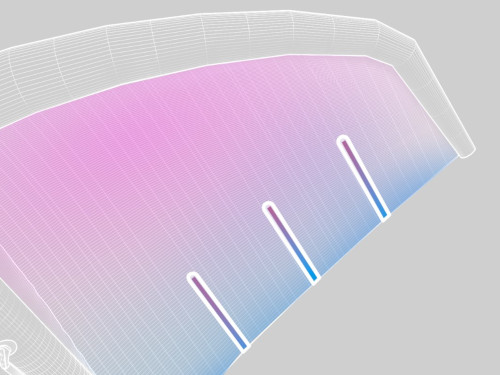

The Trailing Edge may seem loose at first glance but once powered up, it ensures the flattest possible profile at the rear to convert pressure into thrust and to control gusts. NeilPryde composite battens enhance the effect of the flat trailing edge and control unnecessary flutter. Staggered Material Weights in Leading Edge and Strut reinforce the material where needed to support load and provide necessary stiffness. The areas with less load around the tips remain lighter and more flexible. Which not only gives a much lighter feel, but also reduces drag and increases maneuverability due to the thin, angled tips.

The shape of the center strut and the innovative Handle Shape ensure that the Wing is flown as far away from the body as possible. Not only to avoid strong turbulences around the body, but also to make handling and pumping more efficient. In addition, many other details and improvements have been incorporated into the handles. The ergonomic shape of the handles ensures that the position of the wrists always provides the most comfortable and less fatigue - free grip possible. The handles are perfectly balanced for each wing size and offer a longer gripping surface as the wing size increases.

NeilPryde development team has also put their valves to the test and improved them. New Push Valves not only consistently display pressure while pumping, without annoying flickering of the needle, but also pass more air through in less time. The two separate bladders increase safety, while also preventing the strut bladder from serving as an expansion chamber for the front tube bladder and losing pressure and stiffness when needed most. Rounded off with many other small and large details, such as the backpack style bag including helmet, pump holder and foil carry padding, and the best available “made in germany” bladders with Anti - Twist system.

They might not have outrun evolution, but they are convinced that they have made a big step into the future of wing design with the new NeilPryde Fly Wing. NeilPryde team claims: “Just as the real fly often lives a slightly underestimated existence, on closer inspection it is an almost unrivaled masterpiece of natural engineering . We like to see our wings in the same way. Just looking way more sexy then a fly.”

Design

- High Lift Coefficient Concept – Due to the highly refined LE geometry and entry shaping, each wing produces the maximum thrust (power and acceleration) for its size. This dramatically increases the range, allowing riders to use a smaller wing than is typical in each set of conditions. The result is easier handling and greater maneuverability.

- Performance Driven Static Tension Distribution - On the beach, NP wings have a canopy tension distribution similar to a windsurf sail, with maximum tension forward that gradually relaxes towards the trailing edge. Once the wing is loaded, the result is a better flying shape with the camber staying locked forward and a clean trailing edge.

- Modified Delta Planform – This creates a more efficient LE shape and an elliptical spanwise lift distribution for better upwind performance and control.

- Dihedral Front Profile – The dihedral angle allows higher aspect ratios due to increased wingtip clearance and increases performance by making the upper portion of the wing more vertical during straight line flight. It also makes the wing very roll stable, especially when flagging.

- Low Drag Wingtips with Linear Washout – The small LE diameter at the wingtips reduces drag and allows dynamic twist. This improves low end acceleration during pumping as well as control when powered up.

- Vented Strut – The large opening between the LE and the front of the fill panel (which connects the canopy to the strut) allows the pressure to equalize across the two sides of the wing. This improves overall performance and makes the wing even more stable.

Structure/engineering

- High Tension Canopy with Structured Camber Lens – The 3D shape of the canopy leading edge is defined by a series of transverse panels that converge at the wingtips. This leverages the Leading Edge Tube structure to maximize tension in the critical entry sections – the result is more lift and a higher stall angle for better acceleration in light winds, and the ability to fly efficiently at low angles of attack for better control and higher top speeds in strong winds.

- Transverse Canopy Paneling – This construction matches the threadlines of the canopy panels to the load path, making the flying shape more stable and adding long-term durability to the canopy.

- Integral Batten System – sewn-in composite battens create a flat, fast trailing edge with minimum flutter.

- Staggered Material Weights on LE – the use of an ultra-light, high-tenacity woven polyester at the wingtips and back of strut results in a very light ‘feel’ due to reduced swing weight.

- Boundary Panel on Canopy Perimeter – The canopy structure is reinforced with a tough high tenacity rip stop frame that runs down the middle, out the trailing edges to the wingtips and then follows the LE tube back to the center for maximum strength and durability.

- PVC Windows with Structural Elements – High quality polished PVC windows provide maximum visibility, while integral reinforcements carry the transverse loads to minimize canopy distortion and stretch

Handle technology

- Rigid Tubular Handles with Proprietary Base System – Add amazing roll control and comfort while providing the perfect structure to add a harness line.

- Ergonomic Design – The handle bases integrate seamlessly into the strut, while the arc of the handle plane reduces fatigue and positions the wing at the optimum flight angle.

- Integral Impact Protection – The curved front handle has a bumper under the EVA grip to protect you and your board from impact

- Drop Grip Front Handle – the vertical section on the forward handle lets the rider fly the wing further from his body for more efficiency, and further increases the wingtip clearance. It is also ideal for flagging and waveriding due to improved roll control over conventional flagging handles.

- Calibrated Handle Positions – the handles are equidistant from the center of effort on each wingsize for effortless balanced flight. The larger wings feature longer handles to give the rider hand position options to maximize power or reduce fatigue.

Valves & bladders

- Independent LE and Strut valves – the partition adds safety by having two separate air chambers, increases the Leading Edge stiffness (the Strut cannot act as an expansion chamber for the leading edge) and allows the wing to be deflated more quickly.

- Separate Air Chambers

- Push Valve for Quick Inflation & Deflation

- Bladder Made in Germany

- Anti-Twist-System for Bladder

Included with wing

- Backpack Style Wing bag with carry assistant, helm and pump attachment points and various accessory pockets

- Repair Kit (including bladder repair kit, canopy repair patch, canopy material)

Features

High Lift Coefficient Concept

Due to the highly refined LE geometry and entry shaping, each wing produces the maximum thrust (power and acceleration) for its size. This dramatically increases the range, allowing riders to use a smaller wing than is typical in each set of conditions. The result is easier handling and greater maneuverability.

High Tension Canopy with Structured Camber Lens

The 3D shape of the canopy leading edge is defined by a series of transverse panels that converge at the wingtips. This leverages the Leading Edge Tube structure to maximize tension in the critical entry sections – the result is more lift and a higher stall angle for better acceleration in light winds, and the ability to fly efficiently at low angles of attack for better control and higher top speeds in strong winds.

Integral Batten System

Sewn-in composite battens create a flat, fast trailing edge with minimum flutter.

Staggered Material Weights on LE

The use of an ultra-light, high-tenacity woven polyester at the wingtips and back of strut results in a very light ‘feel’ due to reduced swing weight.

Vented Strut

The large opening between the LE and the front of the fill panel (which connects the canopy to the strut) allows the pressure to equalize across the two sides of the wing. This improves overall performance and makes the wing even more stable.

For instant answer - open the chat and ask your question. We're active 9.00-17.00 CET.

Is it afterhours? No problem - leave us a message and we’ll respond early the next day.

+48 513 020 570

For those who prefer phone calls - that's our number. You can give us a ring between 9.00-17.00 CET.

60 days

60 days Guarantee

Guarantee Get

Get Join us

Join us

Facebook

Facebook Instagram

Instagram YouTube

YouTube